A counterflow, concentric tube heat exchanger of a cogeneration system is designed to heat water from an inlet temperature Twi = 5oC to a required outlet temperature Two = 60oC, for which heatfrom an exhaust air stream at Tai = 600oC is recovered. The water stream is flowing through the inner tube at a mass flow rate of mw = 1kg/s, while the air stream passes through the annular region at a mass flow rate of ma = 0.5kg/s.

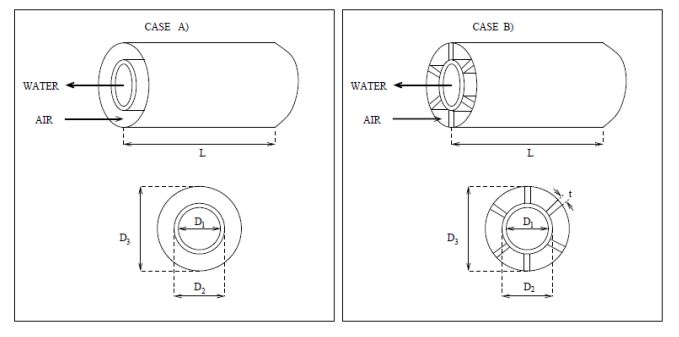

Two different configurations are available for the design: A) two concentric tubes, and B) an innertube connected by six fins to an insulated outer tube. The thickness of the fins is t = 2 mm. The length of the tubes is L. Fins and tubes are made of the same carbon steel k = 50W/mK. The maximum specified length the heat exchanger can occupy in the system is 15m, design lengthsabove that are prohibited by space availability constraints.

For the required outlet temperature Two = 60oC of the water stream and both configurations A) and B):

a) Obtain the outlet air temperature Tao when the heat exchanger operates in steady conditions.

b) Calculate the overall heat transfer coefficient or thermal conductance U as a function of the tube length L.

c) Calculate the logarithmic mean temperature distribution ?Tlm.

d) Calculate the mean temperature increment ?Tm by using an approximate correction factor F = 0.5.

e) Calculate the effectiveness of the heat exchanger and the number of heat transfer units NTU.

f) Estimate the length L of the tubes needed for the specified temperature conditions. Comment on the effect of adding fins and state the best design A) or B) based on 1) material cost and 2) space availability.

Dimensions: D1 = 24 mm, D2 = 30 mm, D3 = 60 mm, t = 2 mm.

Thermodynamic properties of air (T = 380oC): ?a = 0.525kg/m3, Pra = 0.71, ka = 0.0473W/mK, va = 61.52* 10-6m2/s, cpa = 1056J/kgK.

Thermodynamic properties of water (T = 33oC): ?w =995kg/m3, Prw =5.04, kw = 0.620W/mK, vw =0.757* 10-6m2 /s, cpw = 4176 J/kgK.

Write a clear solution, explaining each step, assumptions and calculations.